The packaging and printing industry demands high production efficiency and product quality, and conveyor belts, as critical equipment in production lines, directly impact workflow smoothness and final product outcomes. Choosing the right conveyor belt can enhance productivity while reducing maintenance costs and energy consumption. This article explores how to provide suitable conveyor belts for the packaging and printing industry and introduces key parameters for selection.

Call Us: +86-15026630563

Inquiry Now

Paper and printing industry

**1. Key Requirements for Conveyor Belts in Packaging and Printing**

1. **High-Precision Transportation**

- The industry requires precise transportation systems to prevent misalignment or damage to printed materials during conveyance.

- Conveyor belts must offer stability and consistency to avoid vibrations or slippage that could compromise print quality.

2. **Wear and Corrosion Resistance**

- Exposure to inks, solvents, and other chemicals necessitates corrosion-resistant conveyor belts.

- Long-term operation demands durable materials to minimize wear and tear.

3. **Cleanliness and Hygiene**

- Conveyor belts must be easy to clean to prevent ink or dust buildup, especially in food packaging printing, where compliance with food safety standards (e.g., non-toxic, odorless materials) is critical.

4. **Flexibility and Adaptability**

- Production lines handle materials of varying sizes and textures, requiring adaptable conveyor belts.

- Modular designs may be needed to accommodate frequent adjustments in transportation paths.

2. Key Parameters for Conveyor Belt Selection**

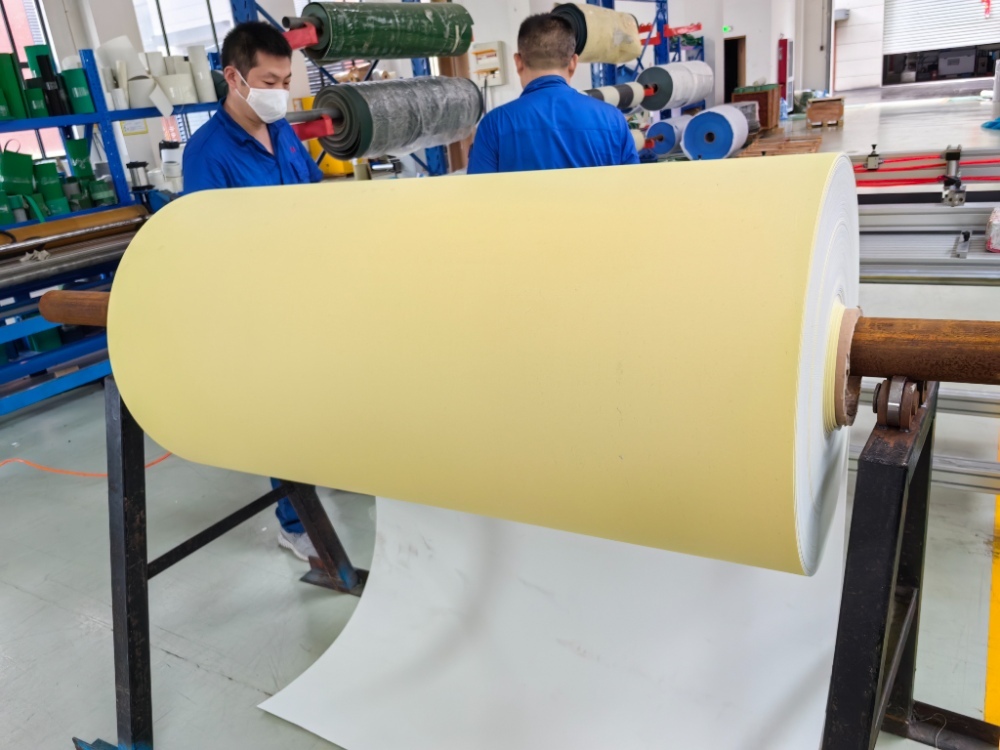

1. **Material Selection**

- **PVC Conveyor Belts**: Suitable for general packaging and printing, offering wear resistance, tensile strength, and easy cleaning.

- **PU Conveyor Belts**: Ideal for food packaging, meeting food safety standards with oil and corrosion resistance.

- **Silicone Conveyor Belts**: Suitable for high-temperature environments (e.g., drying or heating processes).

- **Rubber Conveyor Belts**: Used for heavy-duty packaging materials, offering impact resistance but requiring more cleaning effort.

2. **Width and Thickness**

- **Width**: Typically 10%-20% wider than the largest packaging material to prevent misalignment.

- **Thickness**: Select based on load requirements—1-3mm for lightweight packaging, 4-6mm for heavy-duty applications.

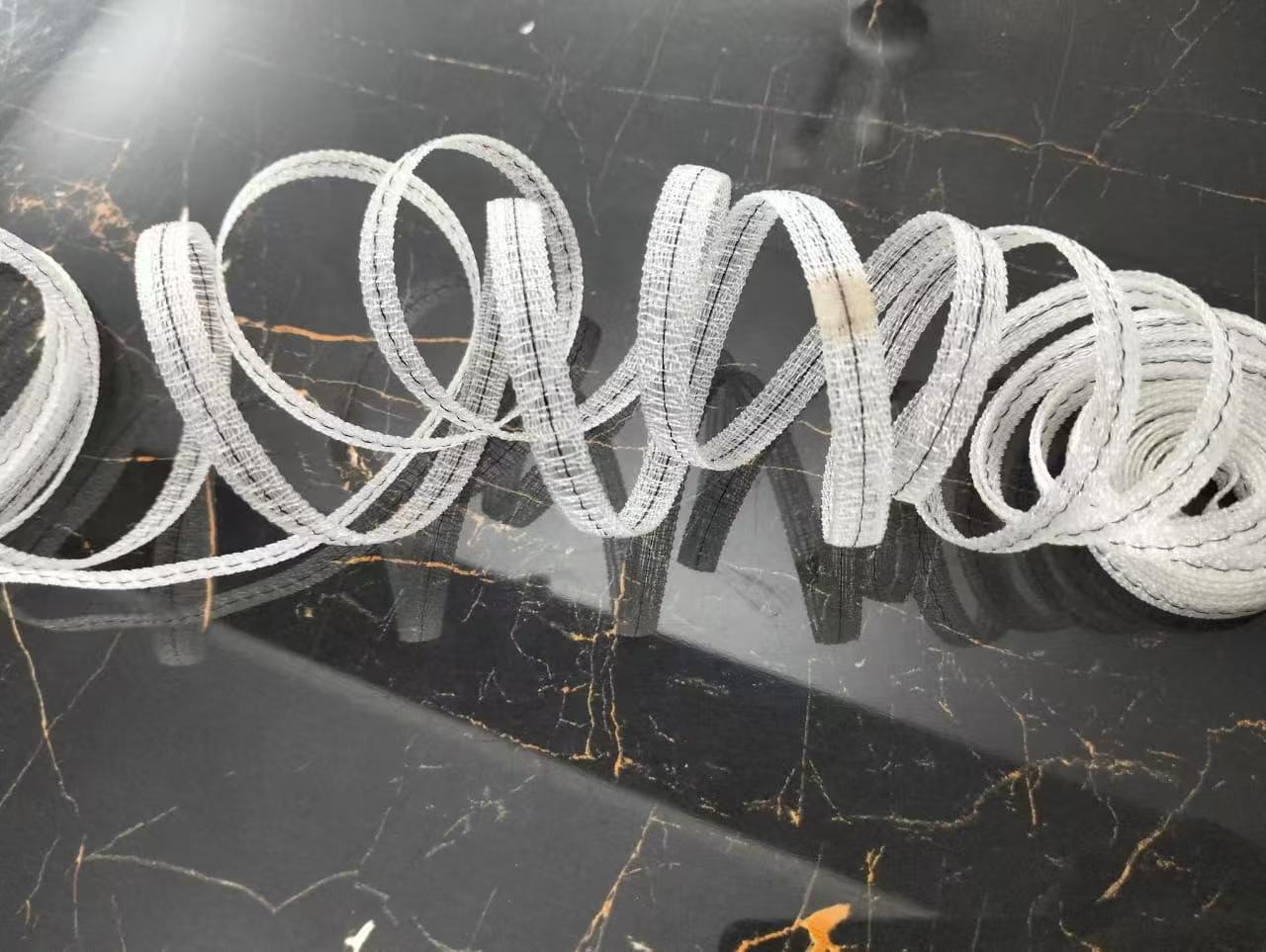

3. **Surface Characteristics**

- **Smooth Surface**: Reduces friction for standard printed materials.

- **Textured Surface**: Enhances grip for inclined transport or heavy packaging.

- **Breathable Surface**: Suitable for drying or cooling processes.

4. **Tensile Strength and Elasticity**

- **Tensile Strength**: Ensure belts withstand prolonged operation without breaking or deforming.

- **Elasticity**: Moderate elasticity protects packaging materials from impact damage.

5. **Temperature Resistance Range**

- Standard belts typically withstand -10°C to 80°C; high-temperature environments require specialized materials.

6. **Operating Speed**

- Match conveyor belt speed to the production line’s workflow to maintain synchronization with printing equipment.

**3. Solutions and Optimization Recommendations**

1. **Customized Design**

- Provide tailored solutions for unique requirements, including specialized dimensions, surfaces, and materials.

- Design dedicated belts for specific processes (e.g., UV printing, foil stamping).

2. **Smart Monitoring**

- Integrate IoT sensors to monitor real-time performance and preemptively address issues.

- Optimize efficiency and reduce energy consumption through data analytics.

3. **Regular Maintenance and Cleaning**

- Offer professional maintenance services to inspect wear and replace belts proactively.

- Recommend cleaning agents and tools to ensure hygiene compliance.

4. **Sustainability and Energy Efficiency**

- Use eco-friendly materials to minimize environmental impact.

- Optimize belt design to reduce energy consumption during operation.

**4. Case Studies**

1. **Food Packaging and Printing Company**

- **Requirement**: Food-safe, oil-resistant, corrosion-resistant, and easy-to-clean conveyor belts.

- **Solution**: PU belt with smooth surface, 600mm width, and 2mm thickness.

- **Result**: 20% productivity increase and 30% reduction in cleaning time.

2. **Luxury Gift Box Printing Company**

- **Requirement**: High-precision transport to prevent print misalignment or damage.

- **Solution**: PVC belt with textured surface, 800mm width, and 3mm thickness.

- **Result**: Product qualification rate improved to 99.5%.

---

Conclusion**

Selecting the right conveyor belt for the packaging and printing industry requires balancing material, dimensions, surface properties, and other technical parameters. Customized designs and smart monitoring can significantly boost efficiency and reduce costs. As technology advances, conveyor belts will continue to play a pivotal role in this industry.

We are a qualified supplier of the world's largest paper making group. Meanwhile, we have cooperated with the largest paper making machinery manufacturer in China for 6 years. Our stable and reliable product quality and excellent after-sales service help us win the trust of more customers.