Call Us: +86-15026630563

Inquiry Now

Part 1:Why Does the Food Industry Require Specialized Conveyor Belts?

-

Food Safety Risks: Industrial-grade belts may leach harmful substances

-

Hygiene Compliance: Mandatory standards under FDA, HACCP, EU 1935/2004 for food-contact materials

-

Operational Demands: Challenges like steam sterilization, freezing temperatures, and oily environments

Part 2:7 Critical Factors for Choosing Food-Grade Conveyor Belts

-

1. Material Selection: Dictates Safety & Durability

-

Common Materials:

-

Polyurethane (PU): food-grade PU conveyor belts,Antibacterial, ideal for baked goods in dry conditions

-

Silicone: High-temperature silicone conveyor belts,Withstands 250°C, suitable for canning sterilization lines

-

Modular Plastic: Easy disassembly, used in meat processing plants

2. Sanitary Design Compliance

-

Seamless Construction: Prevents bacterial growth (3-A Sanitary Standards compliant)

-

Modular Design: Facilitates deep cleaning (BRCGS certified)

-

Anti-Static Treatment: Reduces powder adhesion

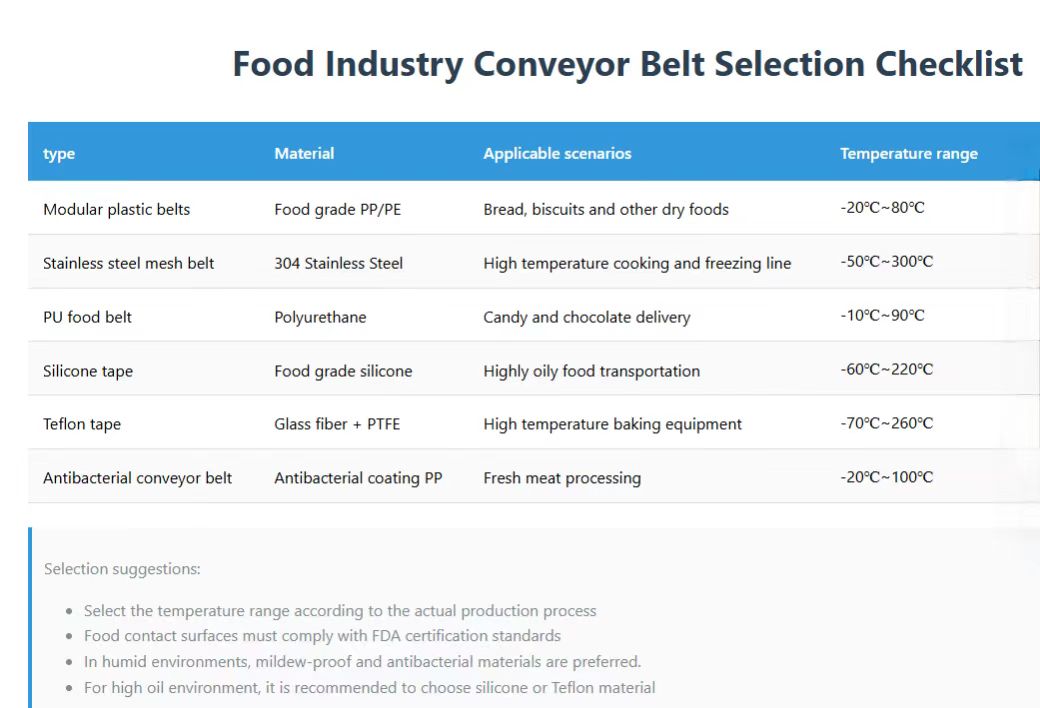

3. Temperature Resistance & Application Matching

-

Freezing: Materials resistant to -40°C brittleness(frozen food conveyor belt materials)

-

High Heat: Belts enduring 100°C+ for hot-fill lines(heat-resistant food conveyor belts)

4. Anti-Slip Textures & Edge Guards

-

Wave/Diamond Patterns: Prevent slippage of produce or packages (e.g., beverage bottling lines)

-

Adjustable Sidewalls: Accommodate varying package sizes

5. Cleaning & Maintenance Costs

-

Compare material resistance to sanitizers

-

Opt for self-lubricating bearings to reduce maintenance

6. Flexibility & Customization

-

Curved belts for space-constrained areas

-

Allergen-free designs for nut processing lines

7. Supplier Certifications

-

Mandatory: ISO 22000 certification

-

Preferred: Vendors offering free material testing

Part 3: Conveyor Belt Solutions for Specific Food Processing Scenarios

-

-

1.Bakery: White PU belts with non-stick coatings(bakery conveyor belt solutions)

-

-

-

2.Meat Processing: Blue antimicrobial modular belts(meat processing conveyor systems) -

-

3.Liquid Packaging: Stainless steel chain belts

-

-

Part 4: FAQs

-

Q1: How often should food-grade conveyor belts be replaced?"Typical lifespan: 2-5 years. Inspect for cracks/deformation quarterly and conduct material safety tests."

Q2: How to verify FDA compliance?"Request a supplier’s Declaration of Compliance and cross-check FDA CFR 21 177.2600."