Silicone timing belt is timing belt coated with silicone by way of scraping and coating. The base belt has two types, one is PU, another is rubber, timing belt teeth profile can be customized, the belt joint has many types, such as flexpfoof, steel buckles, seamless and so on.

Call Us: +86-15026630563

Inquiry Now- Production Factory

- High Quality

- Good Price

- OEM/ODM

Model: SIBR-M

Surface material: milk white silicone

Base belt: rubber timing belt/PU timing belt

Total thickness: 5mm or customized

Thickness of base timing belt: 3.8mm or customized

Thickness of silicone:1.2mm or customized

Core: steel core & Kevlar core& fiberglass core

Maximum tensile strength of 100mm width HTD5M: 2300N

Temperature range: -20~160℃

Peel strength of timing belt with silicone: 6N

Friction coefficient: 0.3

Surface adhension: <10GF

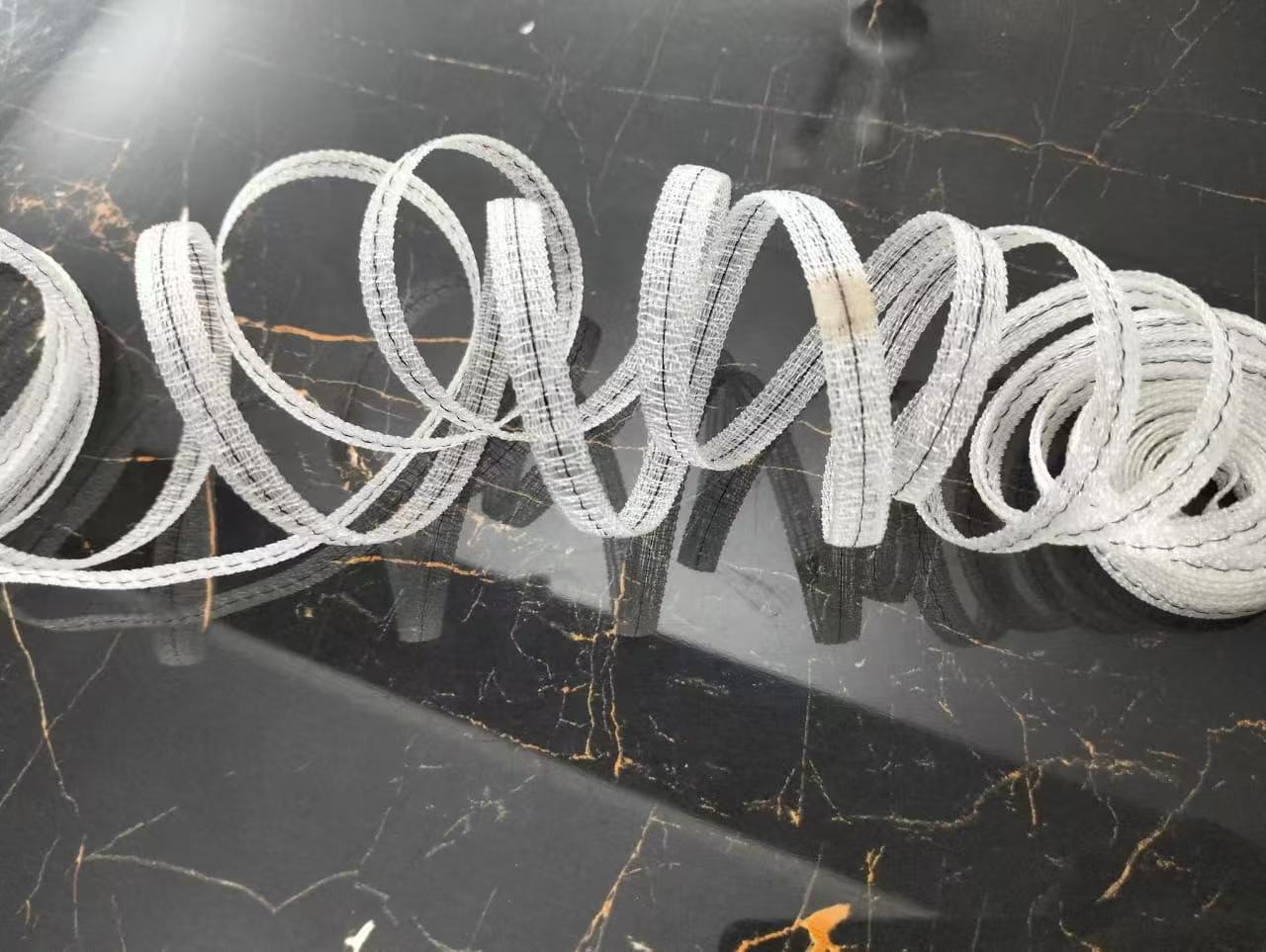

Minimum turning diameter: 25mm

Type: timing belt + silicone

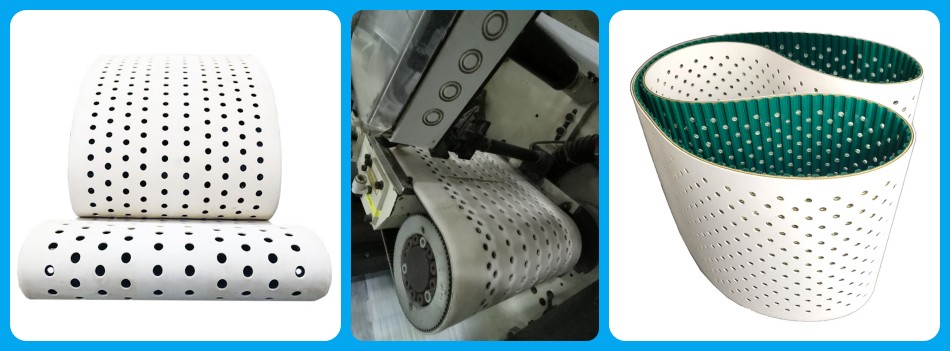

Application: Sanitary napkins, diapers, pull-up pants, adult diapers production line

silicone timing belt has high adhension strength,high temperature timing belt

Silicone timing belt adopts scraping and coating technic after roller extrusion, so it has high bonding strength. In high-speed operation,it is more firm and not easy to fall off powder compared with spraying technic, which greatly improve final yield.

the siliocne layer of the timing belt has features of non-stick, heat resistance and wear resistance

The material of silicone has characteristics of non-stick and heat resistance, and we adopt wear resistant silicone to prevenet drop powder caused by wearing and tearing.

rubber timing belt coated with silicone

The base rubber timing belt temperatre ranges from-20℃ to 160℃, it is suitable for high-speed machine, rotate speed up to 1000-1500 pieces per minute.

pu timing belt coated with silicone

PU and silicone are both food grade, they can contact directly with food. But the pu base timing belt temperature can only up to 80℃.

special technic of silicone timing belt

The thickness of silicone and timing belt teeth profile can be customized, and aslo timing belt can do some more further processing, such as grinding teeth, timing belt adding green fabric.

What are differences between XZ silicone timing with that of other suppliers’?

XZ silcione timing belt adhension process is different from other suppliers, we adopt scraping and coating technics. Compared with glue adhension or spray bonding, our belt will not drop dust, power or crak during performance.

Our company has three patents authorized and eight patents pending. In May 2019, we passed the Shanghai High-tech Achievement Transformation Project, and in September of the same year, we officially became a Shanghai High-tech Enterprise. Since our establishment, our company has been focusing on the industrial belt industry, focusing on innovation, and constantly developing new products, because we believe that innovation is the vitality of the enterprise.

Production Factory

As a manufacturer, we have a standard workshop of 2000 square meters, which has passed ISO9001 quality certificationIn production, we check every level and arrange professional quality inspection personnel to carry out strict quality inspection on the finished products to ensure that each manufactured product is a premium product. Usually, our factory has a large amount of inventory to provide customers with customized services to meet customer's short delivery requirements.

12 Years Industrial Belt Experience

During the 12 years of customer service, we have helped thousands of companies to provide countless solutions to belt problems. From the belt configuration of Mercedes-Benz's automobile production line, the installation and commissioning of the conveyor belt at Nike's logistics center, and the development and application of roll-up belts in steel mills and aluminum plants.We have accumulated a wealth of industrial belt industry experience, and these experiences have motivated continuously develop new products. Whether you are selecting a belt for a new machine or a problem with an existing belt, we are ready to provide you with professional advice and solutions.

Professional Staff

Professional team. Our employees are all professionally trained. Our professionalism and service of sales staff has won praise and recognition from customers. Any inquiry from you will be answered within 24 hours.

OEM/ODM Available

OEM/ODM order available. Reliable machinery has the experience capability and professional R&D team to make any OEM/ODM customer's project, responsible work shop managent follow up and supervise each other.