What kind of wrapper belt is better for cold-rolled steel sheet and aluminum sheet?

Updated: 2022-7-13

The traditional rubber belt meets the oil molecule surface emulsifier pollution steel plate and the roller slips and rolls the steel plate loosely. The PVC joint belt molecule is loose and meets the oil molecule, which will cause cracking, delamination, joint cracking and other phenomena. At present, most of the seamless PU WRAPPER belts are oil resistant, wear resistant, cutting resistant, crack resistant, delamination resistant and extended service life due to the dense molecular combination.

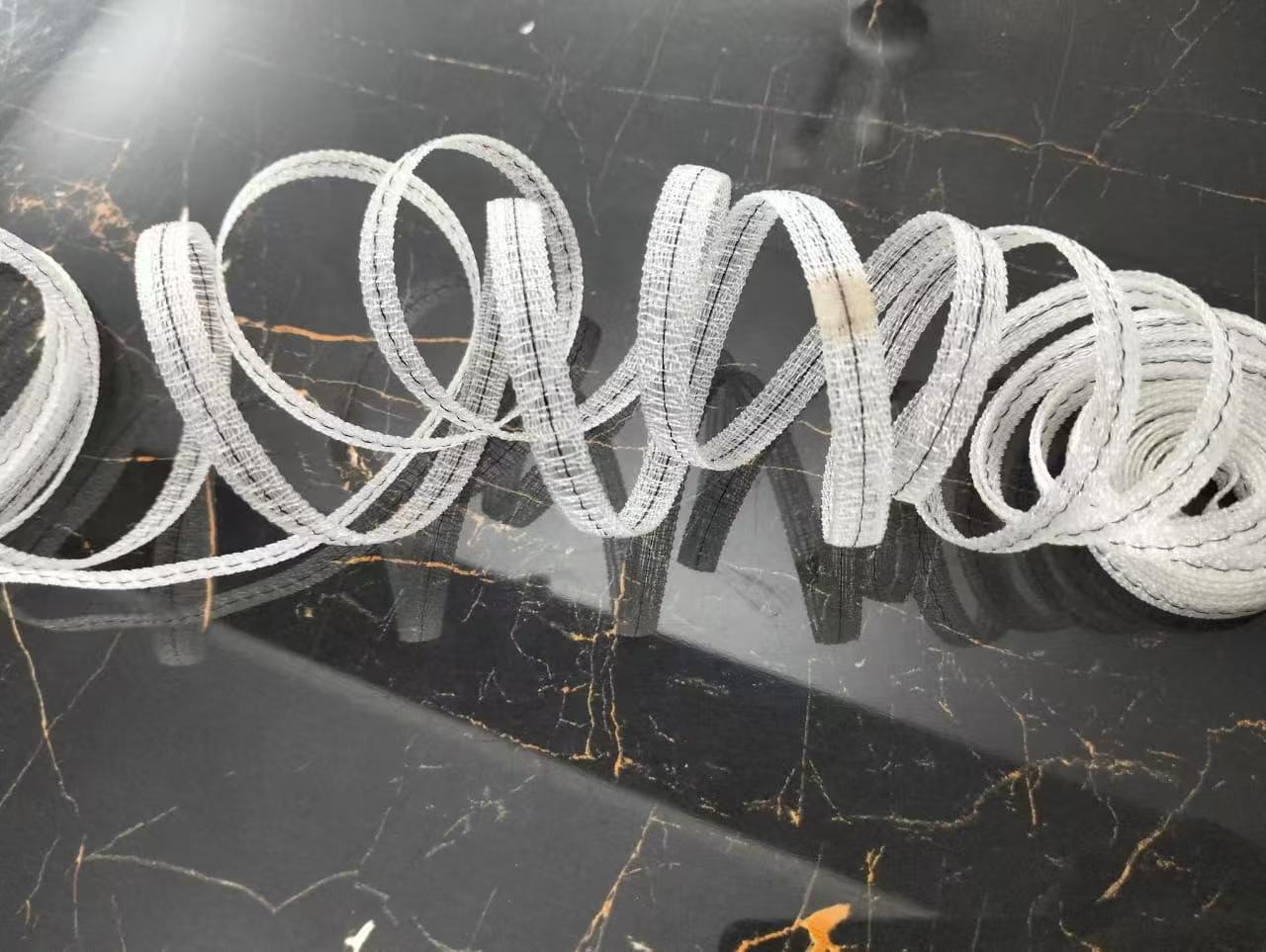

The seamless PU wrapper belt produced by XZBELT Shanghai Xuanze Industrial Belt Co., Ltd. uses the annular seamless knitting process as the tension layer, which has good tensile recovery. The surface is made of oil-resistant, wear-resistant, cutting resistant PU embossing material and the back is made of PU rubber surface material and the roller. During coiling, the friction force due to the contact between the roller and the rubber surface will not cause the steel plate to be loose due to the slipping of the roller and the belt.

At present, there are only a few countries capable of producing seamless PU wrapper belts in the world, including AMMERAAL in the Netherlands, XZBELT in China and ROPPLON in Japan.

The seamless PU wrapper belt produced by XZBELT Shanghai Xuanze Industrial Belt Co., Ltd. uses the annular seamless knitting process as the tension layer, which has good tensile recovery. The surface is made of oil-resistant, wear-resistant, cutting resistant PU embossing material and the back is made of PU rubber surface material and the roller. During coiling, the friction force due to the contact between the roller and the rubber surface will not cause the steel plate to be loose due to the slipping of the roller and the belt.

At present, there are only a few countries capable of producing seamless PU wrapper belts in the world, including AMMERAAL in the Netherlands, XZBELT in China and ROPPLON in Japan.