XuanZe class, let you know the little knowledge related to the help tape?

Updated: 2022-7-13

When it comes to the wrapper belt, what do you think of first? How much do you know about the tape? I'm sure everyone knows a little. Let's follow XuanZe to see.

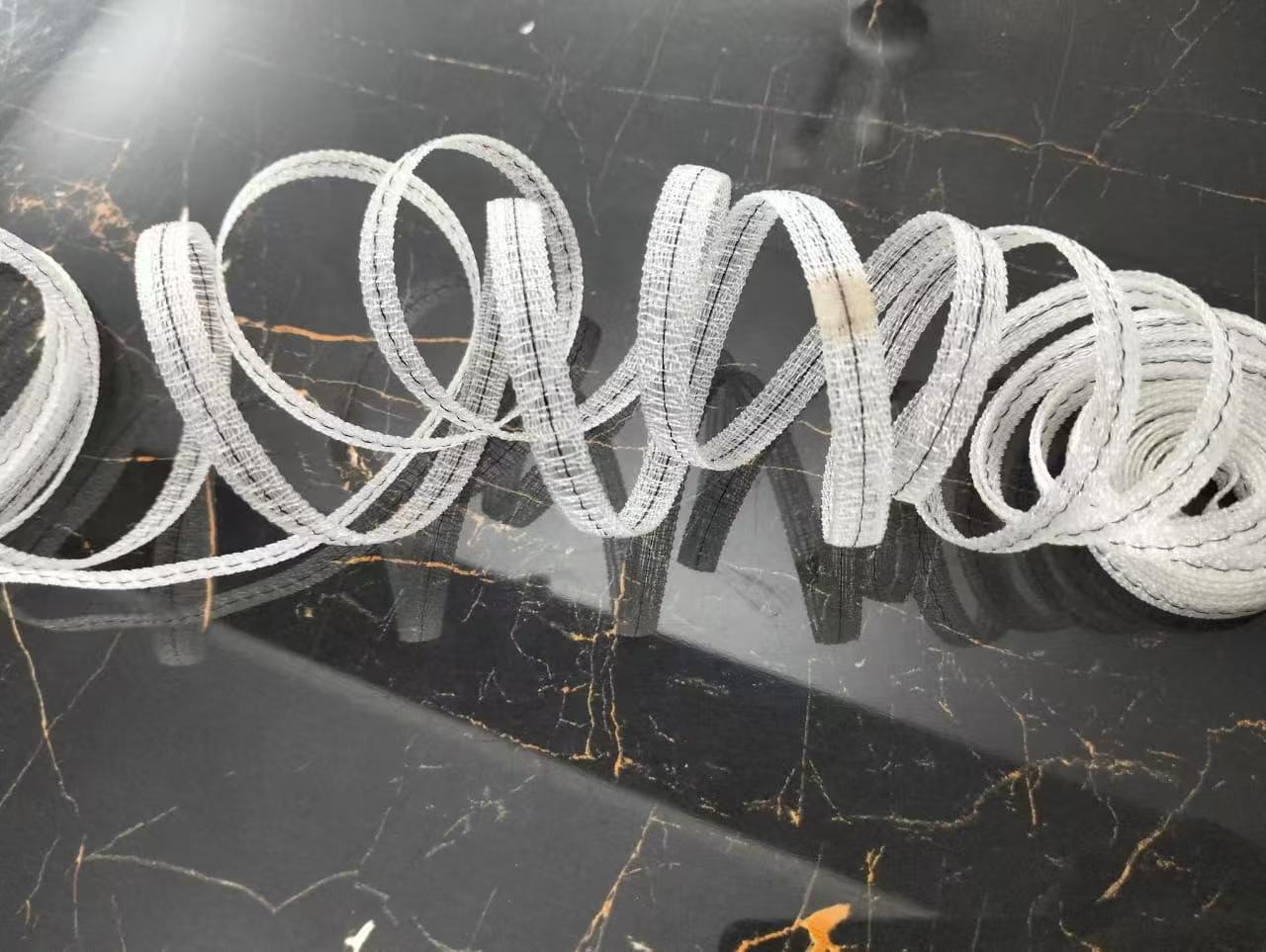

Wrapper belt is the belt on the winding machine of the cold rolling production line. At present, the common wrapper belts on the market are mainly of the following types. The first type is the nylon winding belt made of nylon sheet base and high strength rubber. The second kind: the surface is made of cowhide, and the bottom layer is made of rubber. This is the cowhide wrapper. The third type: nitrile rubber wrapper belt. The fourth kind: PU felt rolling-up belt. By contrast, the nylon wrap and cowhide wrap are limited by raw materials. Because there is no wide nylon sheet and cowhide, they can only be spliced, so their service life is not as long as that of rubber wrap and PU wrap, while PU wrap is high wear-resistant, high strength and high processing cost, so it is not accepted by the majority of users. However, the nitrile rubber wrapper belt produced by our company is not limited by materials and does not need to be spliced. It is not only wear-resistant but also oil-resistant. Manufacturing process This product uses EP cloth with special treatment of high and low strength as the core material skeleton, and then the surface is covered with wear-resistant, temperature-resistant, digging-resistant and anti-aging polymer elastomer (NBR), with stable size, stable operation and long service life. This is also the largest number of wrapper machine belts used in the current market.

Wrapper belt is a special belt with very high requirements for strength and flexibility. Most of them are used in steel, aluminum, copper and other metallurgical industries. It is mainly used for winding machines such as cold-rolled steel sheet, aluminum sheet, copper sheet, stainless steel sheet, and aluminum foil cold rolling, metal sheet, tinplate, aluminum-plastic composite plate, cold-rolled silicon steel, steel mesh and other production lines. This belt is made of high-quality raw materials combined with advanced technology and equipment. The circular base cloth+PU has a flat, soft surface, cutting resistance, no interface, and has excellent characteristics such as cutting resistance, wear resistance, aging resistance, oil resistance and various organic solvents. Product description: production: the yarn is warped and browned and woven into a seamless ring belt; The yarn is a high-strength low-stretch polyester yarn, a counterpoint aramid yarn or a glass fiber yarn; The water content mass percentage is lower than. Features: The winding machine belt has 100% polyester fabric layer, which makes the belt have good resistance to pressure and tension, and will not break the winding machine belt - the strong layer is completely seamless woven, with uniform thickness, flexibility, and accurate size - the winding machine belt - has good oil resistance, can resist a variety of solvents, weak acids, weak alkalis and salts - the surface layer has good cutting resistance (TPU), can adapt to hard working environment - good friction, The steel plate can be more tightly coated with the winder belt - the speed of the conveyor belt is close to the speed tolerance of the drum, so that there is no difference in the speed of two or more belts installed at the same time; It can run at high speed (it can still work well when the speed reaches above 400m/min).

The above is the relevant knowledge about wrapper belt that XuanZe editor brought to you this time. Do you understand? If you want to know more about winding belt and other related knowledge, please pay attention to this column of Hyun Ze, and bring you some relevant knowledge from time to time. Shanghai Hyun Ze Industrial Belt Co., Ltd. is located in the international metropolis of Shanghai, mainly engaged in conveyor belt, plane drive belt, synchronous belt and mechanical parts. The company's products are applied to food, beverage chemical, printing, wood, electronics, aerospace, instrumentation Material conveying system in metering and packaging industries.

Wrapper belt is the belt on the winding machine of the cold rolling production line. At present, the common wrapper belts on the market are mainly of the following types. The first type is the nylon winding belt made of nylon sheet base and high strength rubber. The second kind: the surface is made of cowhide, and the bottom layer is made of rubber. This is the cowhide wrapper. The third type: nitrile rubber wrapper belt. The fourth kind: PU felt rolling-up belt. By contrast, the nylon wrap and cowhide wrap are limited by raw materials. Because there is no wide nylon sheet and cowhide, they can only be spliced, so their service life is not as long as that of rubber wrap and PU wrap, while PU wrap is high wear-resistant, high strength and high processing cost, so it is not accepted by the majority of users. However, the nitrile rubber wrapper belt produced by our company is not limited by materials and does not need to be spliced. It is not only wear-resistant but also oil-resistant. Manufacturing process This product uses EP cloth with special treatment of high and low strength as the core material skeleton, and then the surface is covered with wear-resistant, temperature-resistant, digging-resistant and anti-aging polymer elastomer (NBR), with stable size, stable operation and long service life. This is also the largest number of wrapper machine belts used in the current market.

Wrapper belt is a special belt with very high requirements for strength and flexibility. Most of them are used in steel, aluminum, copper and other metallurgical industries. It is mainly used for winding machines such as cold-rolled steel sheet, aluminum sheet, copper sheet, stainless steel sheet, and aluminum foil cold rolling, metal sheet, tinplate, aluminum-plastic composite plate, cold-rolled silicon steel, steel mesh and other production lines. This belt is made of high-quality raw materials combined with advanced technology and equipment. The circular base cloth+PU has a flat, soft surface, cutting resistance, no interface, and has excellent characteristics such as cutting resistance, wear resistance, aging resistance, oil resistance and various organic solvents. Product description: production: the yarn is warped and browned and woven into a seamless ring belt; The yarn is a high-strength low-stretch polyester yarn, a counterpoint aramid yarn or a glass fiber yarn; The water content mass percentage is lower than. Features: The winding machine belt has 100% polyester fabric layer, which makes the belt have good resistance to pressure and tension, and will not break the winding machine belt - the strong layer is completely seamless woven, with uniform thickness, flexibility, and accurate size - the winding machine belt - has good oil resistance, can resist a variety of solvents, weak acids, weak alkalis and salts - the surface layer has good cutting resistance (TPU), can adapt to hard working environment - good friction, The steel plate can be more tightly coated with the winder belt - the speed of the conveyor belt is close to the speed tolerance of the drum, so that there is no difference in the speed of two or more belts installed at the same time; It can run at high speed (it can still work well when the speed reaches above 400m/min).

The above is the relevant knowledge about wrapper belt that XuanZe editor brought to you this time. Do you understand? If you want to know more about winding belt and other related knowledge, please pay attention to this column of Hyun Ze, and bring you some relevant knowledge from time to time. Shanghai Hyun Ze Industrial Belt Co., Ltd. is located in the international metropolis of Shanghai, mainly engaged in conveyor belt, plane drive belt, synchronous belt and mechanical parts. The company's products are applied to food, beverage chemical, printing, wood, electronics, aerospace, instrumentation Material conveying system in metering and packaging industries.