What should we pay attention to during the installation of conveyor belt?

Updated: 2022-7-13

1. Put a flexible shaft on the conveyor belt coiling iron core, and put the belt coiling properly. Before putting it on the rack, pay attention to the direction of the upper and lower cover rubber.

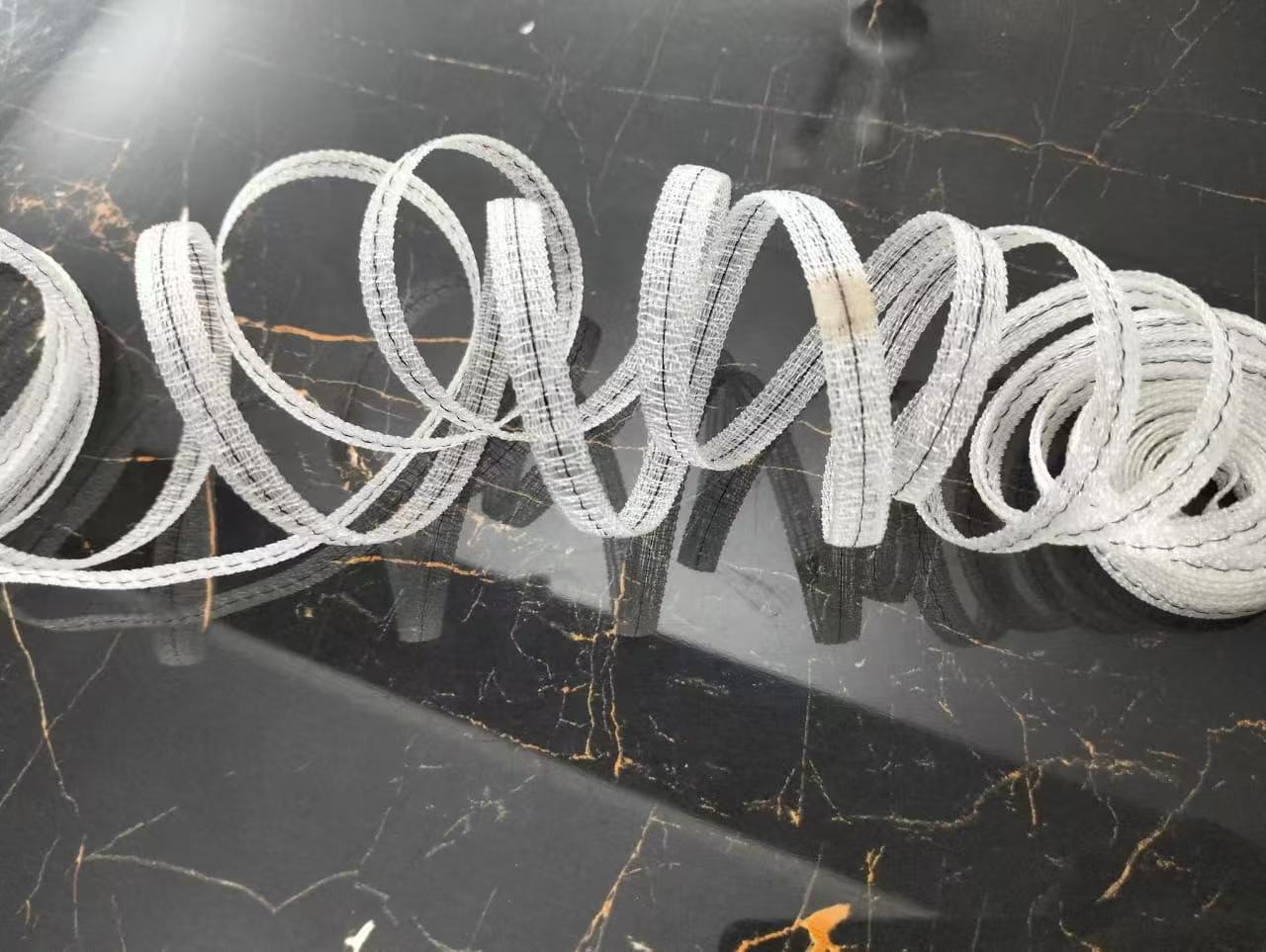

2. In the workplace where it is not suitable to put on the shelf, the conveyor belt can be coiled and guided, and the conveyor belt at the folding position has enough curvature radius to prevent damage to the conveyor belt. It is forbidden to place heavy objects on the conveyor belt at the folding position.

3. If the belt is replaced, the new belt can be connected with the old belt, and the belt unloading and installation of the new belt can be carried out at the same time.

4. For the conveyor running horizontally, the old conveyor can be cut off at any point. For the conveyor running in the inclined direction, the cut-off point should be selected to prevent it from slipping out of control due to its own weight.

5. After the position of the new belt is put right on the conveyor, fix one end of the belt with a clamp, and then connect it around the rope of the roller and the pulley. The conveyor belt is balanced on the conveyor through the traction device. During the traction, the conveyor belt and the frame should be prevented from squeezing each other.

6. Fix one end of the conveyor belt on the conveyor frame with a clamp, and tighten the other end with a pulley until the conveyor belt has no obvious sag on the return idler.

7. Fix the tensioning device 100~150mm from the starting point.

2. In the workplace where it is not suitable to put on the shelf, the conveyor belt can be coiled and guided, and the conveyor belt at the folding position has enough curvature radius to prevent damage to the conveyor belt. It is forbidden to place heavy objects on the conveyor belt at the folding position.

3. If the belt is replaced, the new belt can be connected with the old belt, and the belt unloading and installation of the new belt can be carried out at the same time.

4. For the conveyor running horizontally, the old conveyor can be cut off at any point. For the conveyor running in the inclined direction, the cut-off point should be selected to prevent it from slipping out of control due to its own weight.

5. After the position of the new belt is put right on the conveyor, fix one end of the belt with a clamp, and then connect it around the rope of the roller and the pulley. The conveyor belt is balanced on the conveyor through the traction device. During the traction, the conveyor belt and the frame should be prevented from squeezing each other.

6. Fix one end of the conveyor belt on the conveyor frame with a clamp, and tighten the other end with a pulley until the conveyor belt has no obvious sag on the return idler.

7. Fix the tensioning device 100~150mm from the starting point.