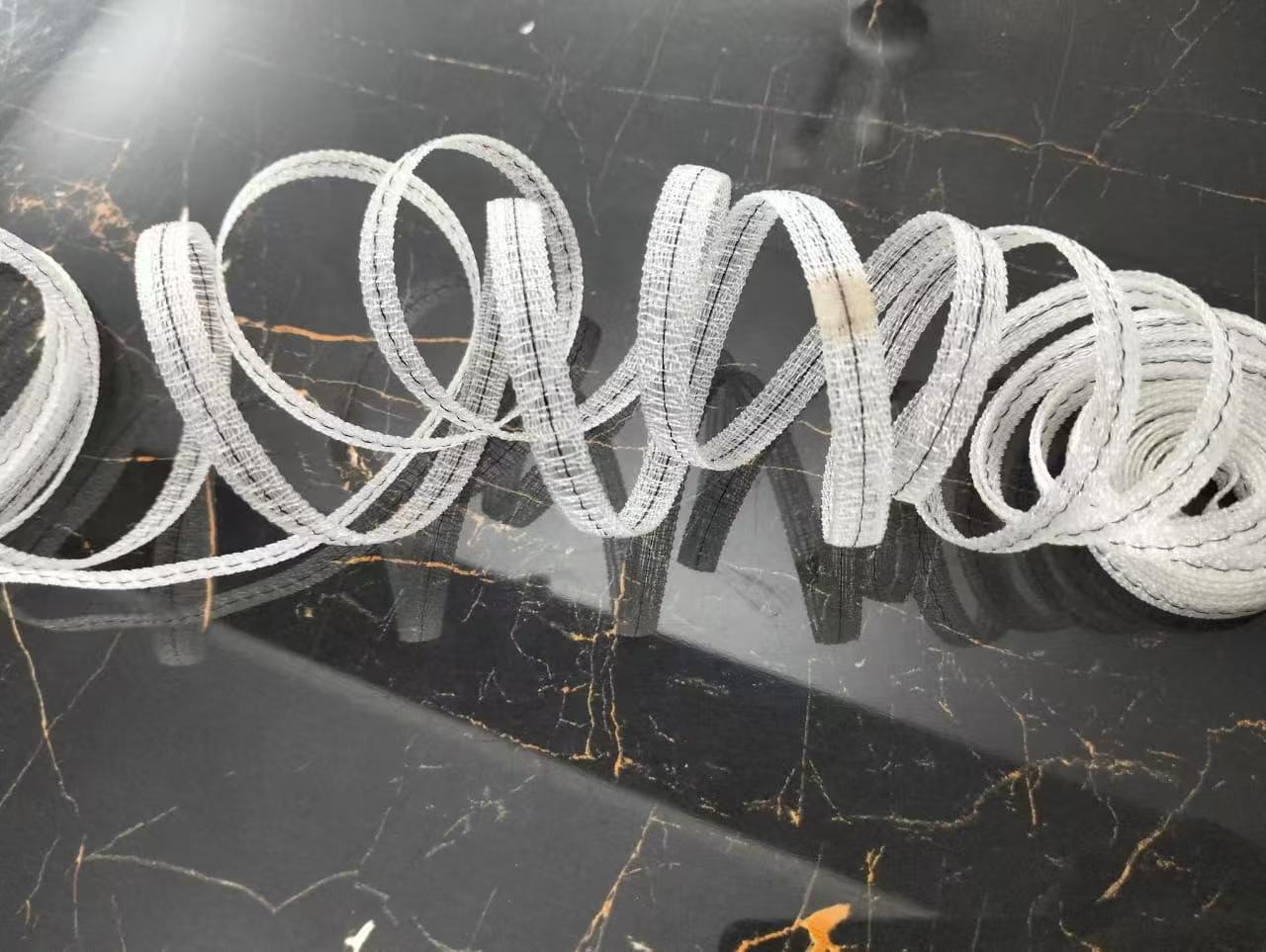

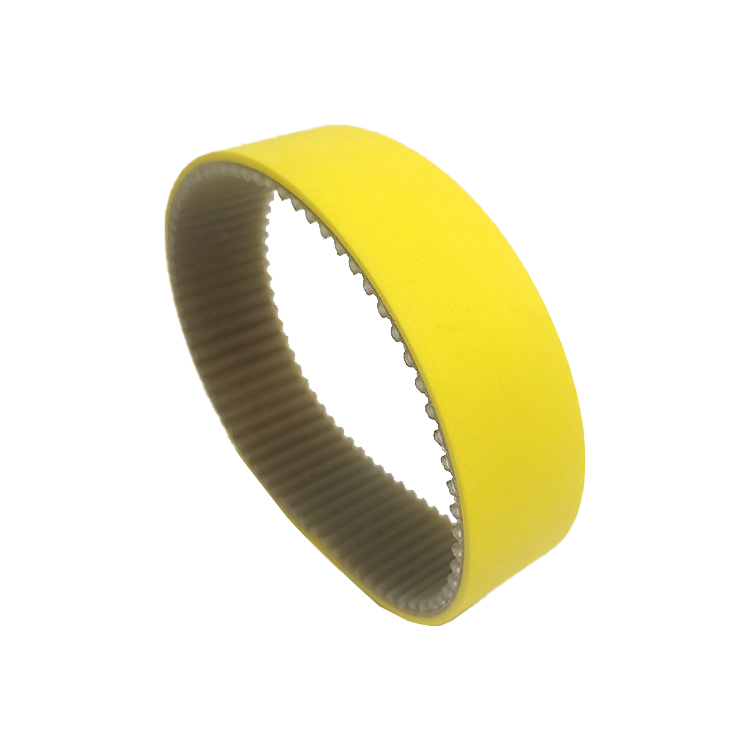

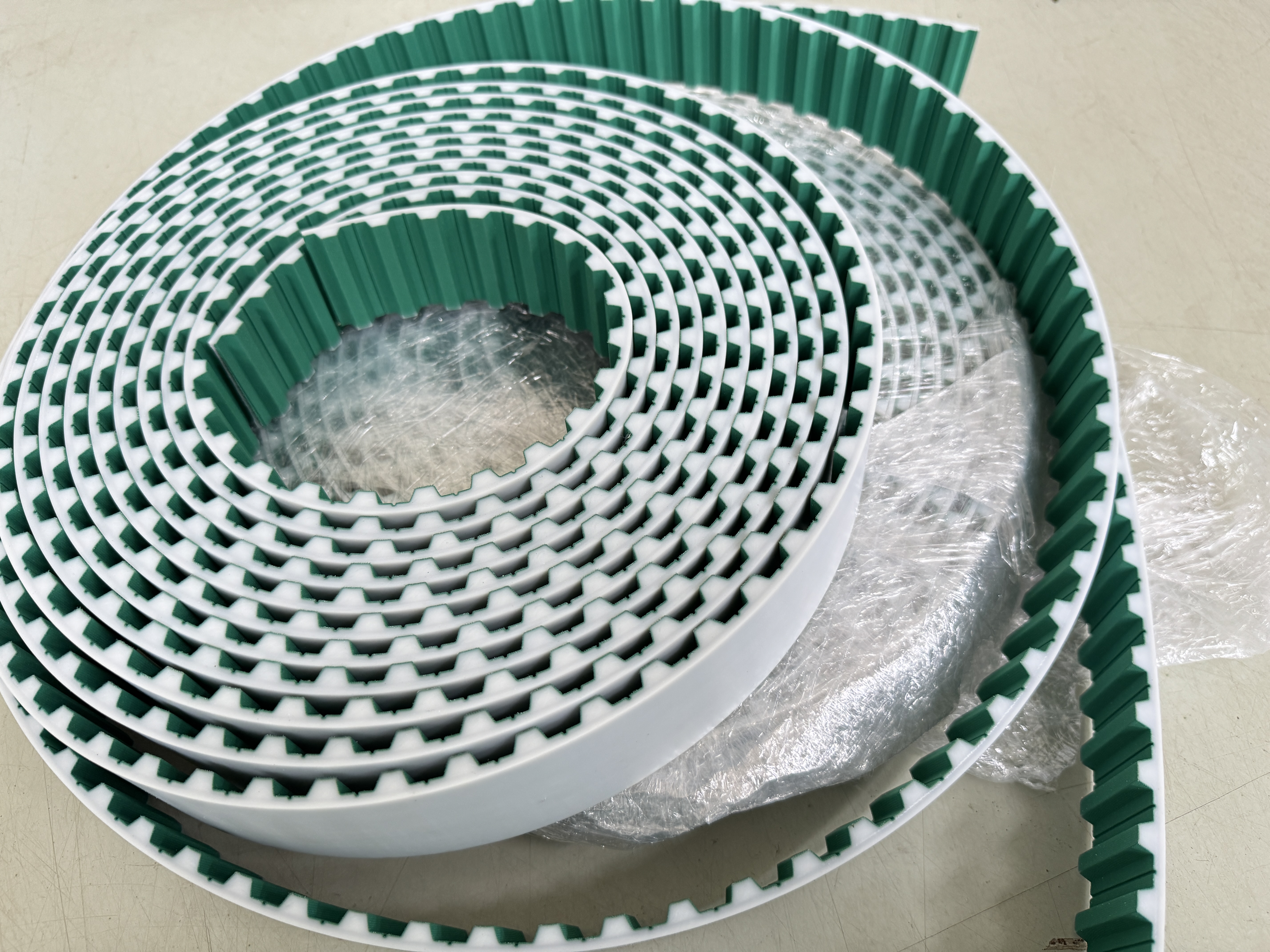

Stripping machine belt is mainly used in various automatic wire harness processing equipment such as wire cutting machine, wire stripper, peeling machine, etc.

Features of belt stripper

1. Large stripping area and fast speed, which can greatly reduce labor intensity and reduce the time required for joints;

2. Light weight, easy to carry and carry;

3. Stable operation.

Call Us: +86-15026630563

Inquiry Now- Production Factory

- High Quality

- Good Price

- OEM/ODM

The most common size of strip stripper belt is T5-455, 5-M-350. At present, there are two main materials: polyurethane and rubber.

Rubber stripper belt, a equipment equipped with four, the service life of about a month. The surface is easy to chip and crack.

Polyurethanes are relatively durable, with four to one device. It's easy to get hard and slippery in winter.

The foaming PU stripper belt produced by our company has good wear resistance and is not prone to hard slipping under cold conditions, which greatly improves the service life of the stripper belt. In addition, since it is developed and produced by our factory, the delivery time is guaranteed.

The stripping area of the stripper belt is relatively large and the speed is very fast. The full automation greatly reduces the labor intensity, thus reducing the labor consumption, reducing the time required for the joint, and increasing the production capacity;

The stripper belt is used to fasten and clean the rubber layer at the head of the conveyor belt when preparing the belt joint. This operation can be used in various occasions and places, and it is light in weight, easy to carry and carry;

The stripper belt is seamless and stable in operation. There are few stoppage cores, so the stability of the machine is the highest and the overall production is improved.

Our company has three patents authorized and eight patents pending. In May 2019, we passed the Shanghai High-tech Achievement Transformation Project, and in September of the same year, we officially became a Shanghai High-tech Enterprise. Since our establishment, our company has been focusing on the industrial belt industry, focusing on innovation, and constantly developing new products, because we believe that innovation is the vitality of the enterprise.

Production Factory

As a manufacturer, we have a standard workshop of 2000 square meters, which has passed ISO9001 quality certificationIn production, we check every level and arrange professional quality inspection personnel to carry out strict quality inspection on the finished products to ensure that each manufactured product is a premium product. Usually, our factory has a large amount of inventory to provide customers with customized services to meet customer's short delivery requirements.

12 Years Industrial Belt Experience

During the 12 years of customer service, we have helped thousands of companies to provide countless solutions to belt problems. From the belt configuration of Mercedes-Benz's automobile production line, the installation and commissioning of the conveyor belt at Nike's logistics center, and the development and application of roll-up belts in steel mills and aluminum plants.We have accumulated a wealth of industrial belt industry experience, and these experiences have motivated continuously develop new products. Whether you are selecting a belt for a new machine or a problem with an existing belt, we are ready to provide you with professional advice and solutions.

Professional Staff

Professional team. Our employees are all professionally trained. Our professionalism and service of sales staff has won praise and recognition from customers. Any inquiry from you will be answered within 24 hours.

OEM/ODM Available

OEM/ODM order available. Reliable machinery has the experience capability and professional R&D team to make any OEM/ODM customer's project, responsible work shop managent follow up and supervise each other.